LNG import terminals are one of the actions, taken by EU countries, to cope with the energy shortage that followed the Russian invasion of Ukraine and the destruction of the Nordstrom pipeline. This sudden lack of natural gas supply brought about the urgent construction of LNG import terminals. There were 35 operational LNG import terminals in Europe as of January 2024, and 17 more planned or under construction. Of these, 23 are FSRU terminals (1). A Floating Storage Regasification Unit (FSRU) is a floating vessel that can transport, store, and re-gasify liquefied natural gas (LNG) onboard.

Some of the import terminals use a leased FSRU ship as an intermediate solution until an onshore import terminal is built. Germany, Italy, and Greece are the countries leading the implementation of this solution.

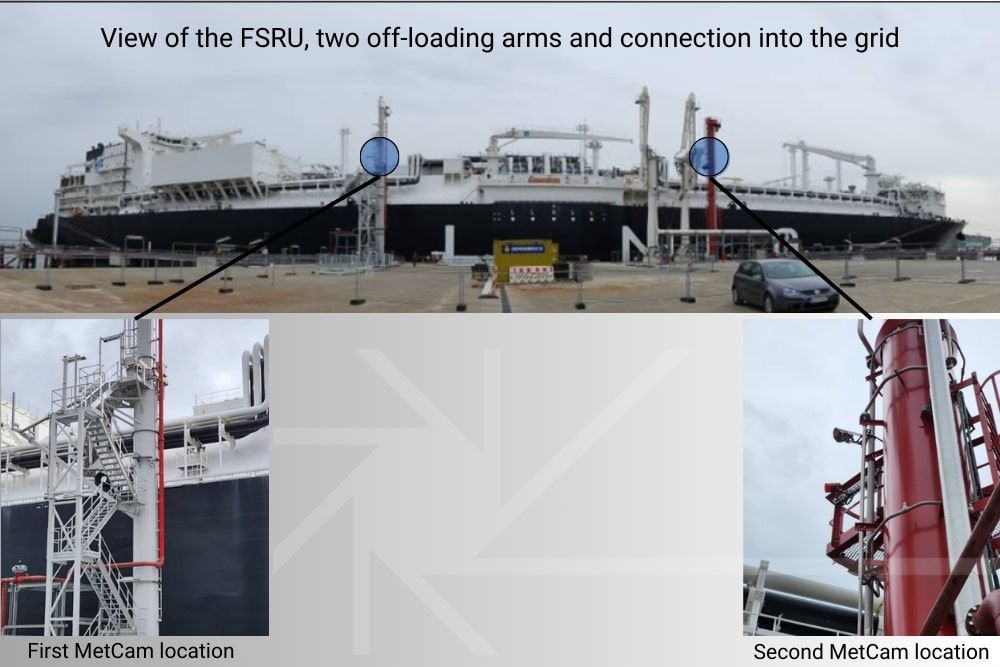

The main onshore facilities of an import terminal are the off-loading arms and the control valve system regulating the high-pressure flow of gas from the FSRU into the grid. These are critical elements and detecting gas leaks in this sensitive area is very important. With the rising amount and capacity of FSRU’s in Europe, continuous safety solutions are needed to secure these facilities.

The MetCam units were aimed at the pressure control valve array to enhance safety and reduce the response time in case of a leak.

The MetCam units are used in a unique way, implemented as volume gas detectors where they only connect with 24VDC and 4-20 mA. The Zone 1 certification of MetCam allows this installation, since all the equipment on site must be HazLoc certified.

The data from MetCam is self-contained and not required to be fed into any video stream or external computer system. The 4-20 warning alarm signals are produced on-board the unit and are fed into the existing site safety infrastructure that includes Drager Polytron point and flame detectors, all feeding into a common SCADA system.

Thanks to MetCam’s large field of view, only 2 units are needed to monitor the entire critical asset. One unit is installed on a pole 40 meters away from the valve array. The second MetCam is installed above the valves, about 15 meters up.

Coverage by MetCam installed 40 meters away

Coverage of MetCam installed above the valves

Following installation, MetCam was set with 2 thresholds for alarms, determined by the size, density and persistence required for a fugitive gas cloud to accumulate into a potentially explosive cloud. Once an alarm triggers, an event is created and stored on the internal memory, allowing the operator the option to investigate the causes for the safety event.

By leveraging the capabilities of optical gas imaging for safety applications, LNG terminal operators can accelerate their detection and response time to gas leaks, enhancing site safety and securing continuenous operational conditions.

(1) Data source: https://www.gie.eu/transparency/databases/lng-database/